High Barrier Laminating Food Packaging Rollstock Film

Products Features:

Roll film is a laminated flexible packaging film that is rolled up and used as a semi-finished packaging bag. The production process for roll film packaging is simpler than that of finished bags, as it only requires printing and lamination without cutting and folding. This makes it a cost-effective option that is ideal for fast-moving consumer products. We provide roll film in up to 11 different colors and can tailor the film for various constructions, making it suitable for all types of products on vertical or horizontal form fill and seal bagging machines.

Custom Options:

1. Film size:

Customers have the option to customize the size of their roll film according to their specific requirements (length*width).

2. Printing colors: up to 11 colors

3. Roll film material structure and thickness:

Different types of laminate structures are available for flexible packaging web films, including various outer layer options such as PET, BOPP, Kraft paper, and Nylon, intermediate layer options like PET, VMPET, Kraft paper, Aluminum foil, and Nylon, and inner layer options such as PE and CPP. Customers can customize two-layer, three-layer, and four-layer composite packaging films based on their specific needs.

4. Surface treatment:

1) Matt;

2) glossy;

3) Velvet soft touch matte;

4) Spot UV printing (part glossy and part matt)

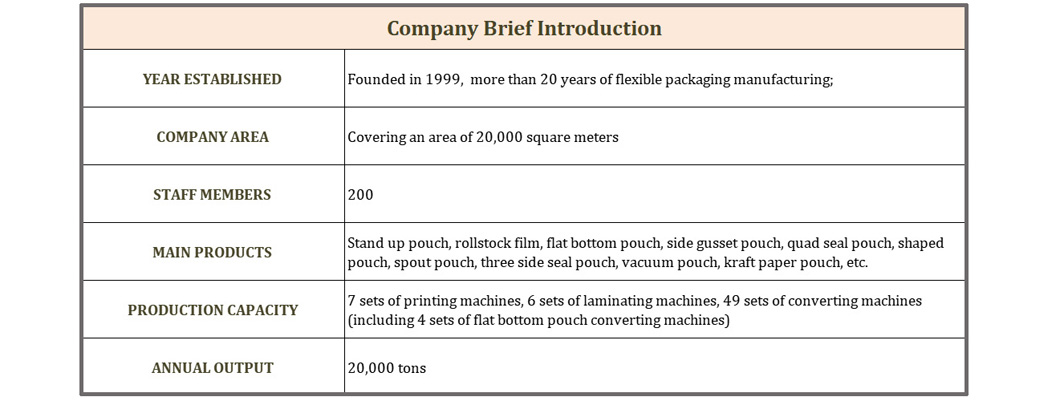

Company Introduction

Our Services

We specialize in providing top-notch custom printed food packaging bags, including stand up pouches, three side seal pouch, kraft paper pouch, flat bottom pouch, side gusset pouch, coffee pouches, etc. for both the food and non-food industries. Our factory culture revolves around delivering high quality products, excellent service, and competitive prices.

1. State-of-the-Art Printing Technology

Our state-of-the-art printing technology, equipped with the latest advanced machines, ensures that our products meet high-quality standards and offers a variety of options.

2. On-Time Delivery

With our automatic and high-speed production line, we guarantee efficient production and on-time delivery to our customers.

3. Quality Guarantee

Our well-trained quality control staff meticulously reviews every step of the production process, from raw materials to finished products, to ensure that our products meet the highest quality standards.

4. After-Sale Services

We prioritize customer satisfaction by promptly addressing any questions or issues that may arise, and taking full responsibility to resolve them.

FAQ:

Q1: Are you a producer of flexible packaging bags?

Yes, we are a seasoned flexible packaging manufacturer with 23 years of experience. Our factory is situated in Shandong Province, China, with an area of 20,000 square meters.

Q2: What are the minimum order quantities?

For digital printing, the MOQ is 500pcs; for gravure printing, it is around 20,000 pcs, based on bag size.

Q3: How can I obtain the complete price? ?

Kindly provide us with specifics (such as pouch type, dimensions, material, thickness, printing colors, quantity, special attributes) regarding your products.